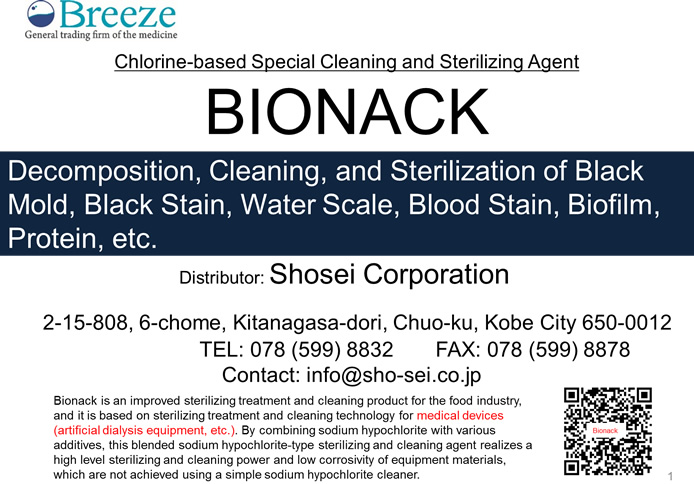

Waste Storage Room: Test for Removal of Deposits on Stairs Bionack AS-70

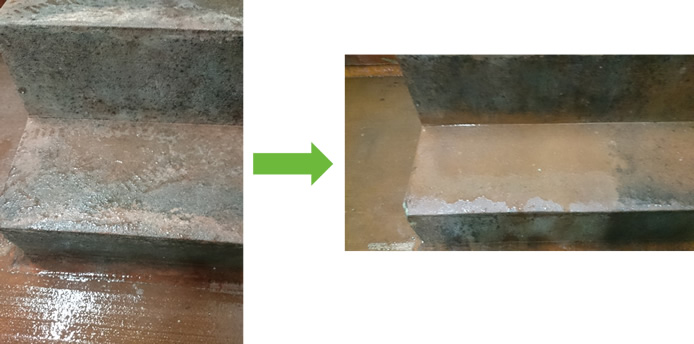

Waste Storage Room: Test for Removal of Deposits on Pillar Bionack AS-70

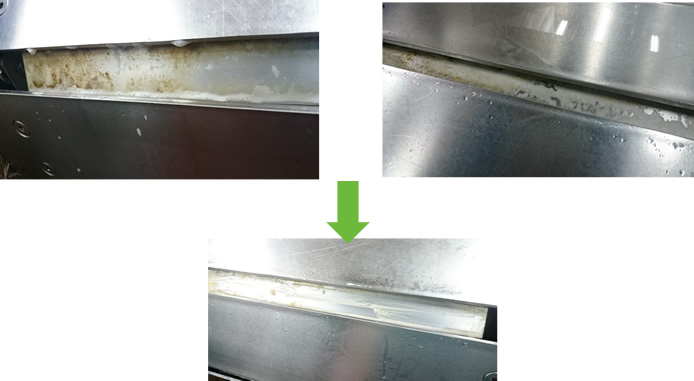

Organs Conveyor: Test for Removal of Surface Contamination Bionack AS-70

Special Cleaner Bionack

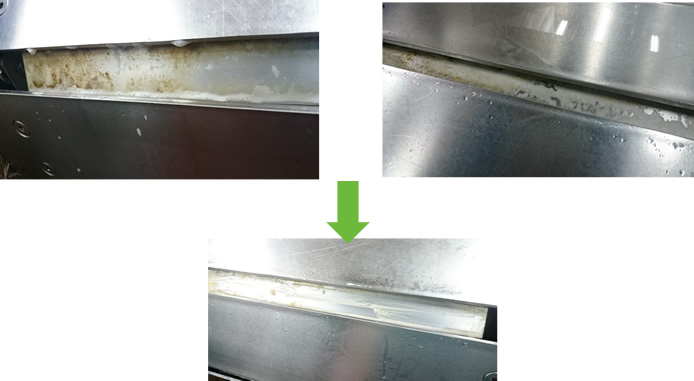

Meat processing plant: Example of cleaning blood and black stains

Special Cleaner Bionack

Meat processing plant: Example of

cleaning oil and fat stains

Special Cleaner Bionack

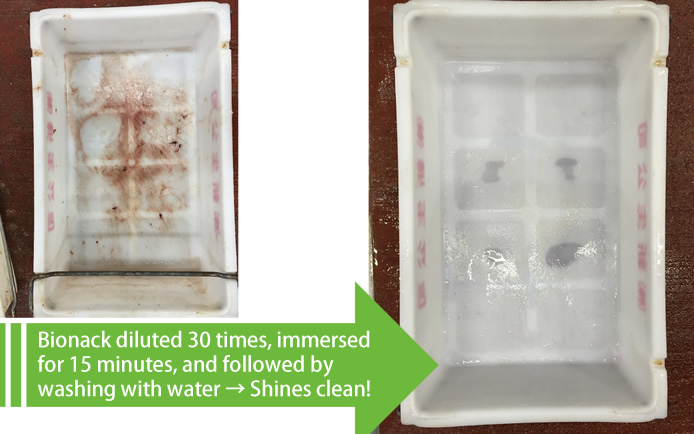

Drain filter: Example of cleaning slime

Special Cleaner Bionack

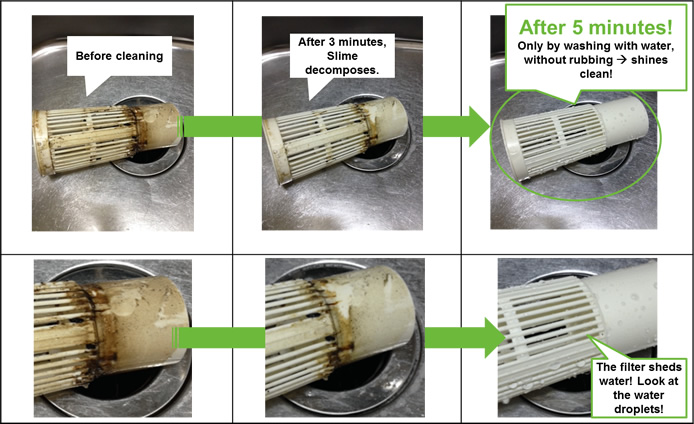

Chicken processing plant: Example of cleaning of black stains

Special Cleaner Bionack

Chicken processing plant: Example of cleaning of black stains

Special Cleaner Bionack

Vegetable cutting plant: Example of cleaning black stains

Foam-cleaning Farm Gun

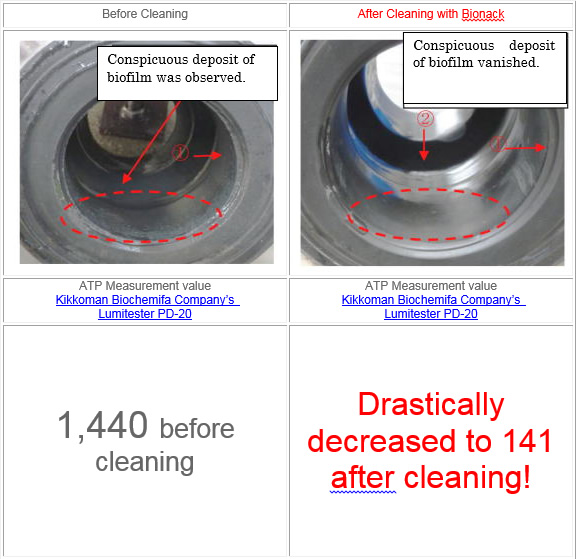

Cleaning and Sterilization of Deposited Foreign Matter on the Inner Surface of the Flexible Joint for High-Pressure Pump

ATP measurement results

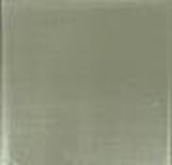

| Bionack | 6% NaClO Sodium hypochlorite |

Water purified using reverse osmosis (RO) | ||

|---|---|---|---|---|

| Appearance |

NaClO 6% Diluted 50 times Immersion for 14 days |

|

|

|

|

NaClO 6% Diluted 5 times Immersion for 14 days |

No corrosion was observed |

Corrosion observed. |

No corrosion was observed. |

|

| Corrosion rate by weight (gmh) | Diluted 50 times | 0.0002 | 0.0311 | 0.0001 |

| Diluted 5 times | 0.0003 | 0.1324 | ||

| Corrosion rate by depth(mm/y) | Diluted 50 times | 0.0002 | 0.0344 | 0.0001 |

| Diluted 5 times | 0.0003 | 0.1450 | ||

| Remarks | – | With pitting corrosion | ||

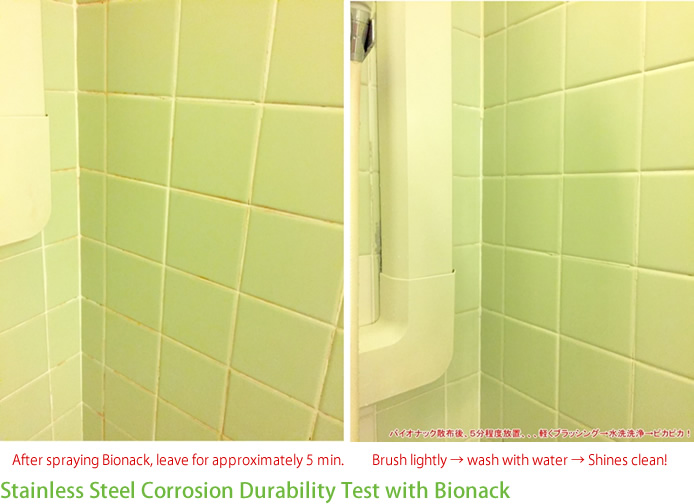

Appearance, measurement results of corrosion rate by weight and corrosion rate by depth of SUS304 sample after deterioration test

-

Evaluation method

– Test material: SUS304 (30 × 40 × 0.5 mm), Test repeated twice at each level

– Test cleaner: Bionack AE-200 and 6% NaClO (Diluted 50 times and 5 times, respectively), RO water

– Test method: Immersion for 14 days in a test liquid at 55°C (Replaced by fresh test liquid every three days)

- Results: Corrosion rate of Bionack on SUS304 was less than NaClO, and the occurrence of pitting corrosion was not observed.

Summary

- Strong penetrating power of the surfactant contributes to improve the cleaning power and facilitates sodium hypochlorite to exert the effect in decomposing protein and fat.

- Although this is a chlorine-based chemical, its influence on metal and other materials is negligible, and the damage to the equipment can be reduced as compared with ordinary sodium hypochlorite.

Characteristics

- Strong cleaning power eliminates bacteria in the decomposing protein, fat, and sugar.

- The surfactant with a strong penetrating power of surfactant penetrates deep in the dirt and facilitates sodium hypochlorite to exert the effects.

- Although this is a chlorine-based chemical, it exerts a negligible influence on metals. *The extent of corrosion is 1/264 of that of the ordinary sodium hypochlorite.

- This product can be used for sterilizing and cleaning of equipment that cannot be reached by hands.

Procedures for Use

- Wash the target equipment fully with water.

- Dilute the original liquid in accordance with the amount of deposits and immersion time.

*5 times (200 mL per L) to 200 times (5 mL per L) - Spray the diluted solution on the equipment, or immerse the equipment in the solution and leave it for a while.

- Wash thoroughly with water.

*Please check for residues by using commercially available reagent for detection of chlorine residues.

Examples of Applications

- Decomposition, cleaning, and sterilization of biofilms and other deposits in filling lines and tanks of mineral water.

- Decomposition, cleaning, and sterilization of deposits in the lines, tanks, and ovens in food factories.

- Cleaning and sterilization of circulating bathtub and inner surface of the piping of spa facilities (super public bath).

- Removal of oil dirt in kitchens

- Decomposition, cleaning, and sterilization of black mold and other deposits on the inner walls of tanks.